Determine Load-Bearing Requirements Based on Electric Tool Specifications

Why Electric Tools Require High-Load Customized Gift Boxes

Electric tools typically weigh between 8 and 22 pounds, with industrial models exceeding 40 pounds. Standard packaging often fails under this weight, leading to crushed corners and product damage during transit. High-load customized gift boxes solve this with engineered designs that distribute weight across reinforced seams and load-bearing walls, preserving product integrity.

Understanding Load-Bearing Capacity in Relation to Box Structure

A box’s ability to support weight depends on three key factors:

- Material rigidity (measured via Mullen burst tests)

- Wall thickness (single or double-wall corrugated board)

- Internal support systems (partition walls, die-cut trays)

For example, a 200#/ECT-32 corrugated box can withstand up to 265 lbs of stacking force—essential for multi-tiered pallet shipments in warehouse environments.

Analyzing Failures from Under-Engineered Packaging in Tool Shipments

A 2023 logistics study found that 23% of power tool damage claims resulted from boxes deforming under less than 450 lbs of vertical pressure—a common load in stacked pallets. Weak adhesive bonds and insufficient flute height were identified as primary structural weaknesses.

Aligning Box Strength with Product Weight and Handling Conditions

To ensure protection, match box specifications to:

- Tool weight: Use double-wall construction for tools over 25 lbs

- Transit hazards: Add edge protectors for international shipments

- Storage duration: Apply humidity-resistant coatings for storage above 70% RH

Validate all designs using ISTA 3A testing, which simulates real-world vibration, drops, and compression forces.

*Average weights derived from leading manufacturers’ 2024 product catalogs

Evaluate Material Composition for Maximum Durability in Customized Gift Boxes

How Corrugated Fluting Enhances Crush and Impact Resistance

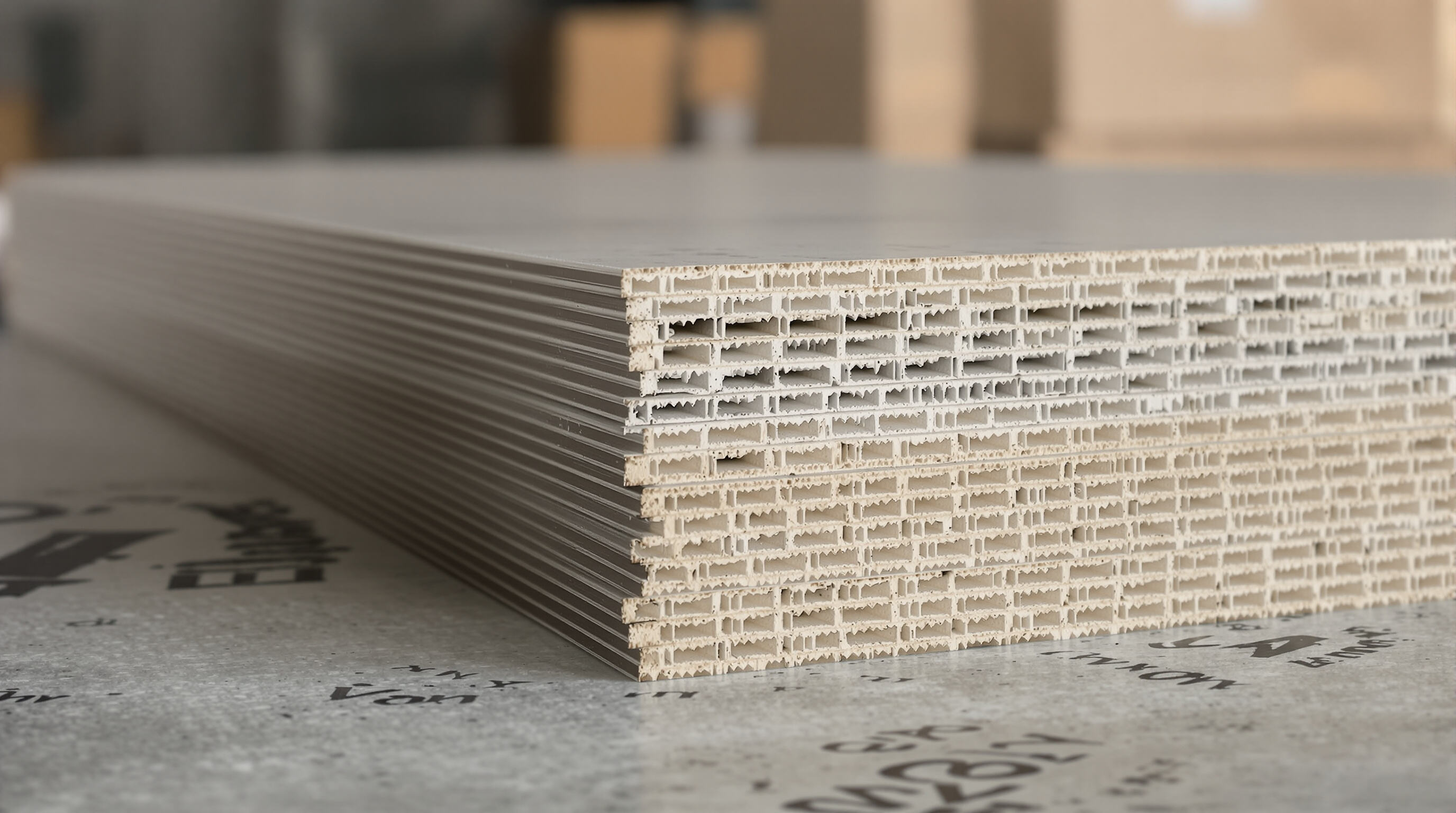

What makes corrugated materials so effective? Well, they have those wave-like flutes that actually spread out stress across their surface. According to research from Packaging Dynamics back in 2023, these materials can absorb about 60 percent more impact compared to regular paperboard sheets. Between each layer there are tiny air spaces that work kind of like cushions, which helps protect stuff when it gets dropped or bumped around during shipping. Especially important for things like power tools that weigh quite a bit. When we talk about double wall construction versus single wall, the difference becomes really noticeable. Double walls handle roughly 2.8 times the weight stacking pressure without collapsing, so they're much better suited for packing odd shaped items or anything particularly heavy that needs extra protection while being transported.

Grammage, Caliper, and Rigidity: Key Material Specifications

Durability is determined by three measurable properties:

- Grammage (180—400 gsm): Higher density improves puncture resistance

- Caliper (2—6 mm): Thicker boards resist crushing under vertical loads

- Rigidity (≥ 65 lbf/in²): Ensures walls maintain shape under dynamic stress

One manufacturer reduced warranty claims by 33% after switching to 275 gsm kraft boards with a 4.2 mm caliper for angle grinder packaging.

Comparing ECT and Mullen Values Across Rigid Board Types

| Property | Corrugated (32 ECT) | Solid Fiberboard (55 ECT) |

|---|---|---|

| Edge Crush Test | 32 lb/in | 55 lb/in |

| Mullen Burst Test | 200 psi | 275 psi |

| Moisture Resistance | Moderate | High |

While ECT predicts compression strength along the edge, Mullen values reflect overall bursting resistance. Heavy-duty shipments often require 44 ECT boards, capable of withstanding 1,100 lbs/ft²—equivalent to eight stacked pallets.

Solid Fiberboard vs. Corrugated Composites: Pros and Cons

Solid Fiberboard

- “ Superior print surface for premium branding

- › 23% heavier than comparable corrugated options

Corrugated Composites

- “ 40% better vibration damping (ISTA 3E testing)

- › Requires storage below 60% RH without climate control

Advances in polymer-coated flutes now allow corrugated boxes to retain 98% of their strength at 85% humidity, closing the performance gap with moisture-sensitive fiberboard.

Single-Wall vs. Double-Wall Corrugated: Choosing the Right Protection Level

Drop Test Performance: Single-Wall vs. Double-Wall Customized Gift Boxes

Testing results indicate that double wall corrugated boxes can handle about 62 percent more impact force compared to their single wall counterparts during standard drop tests. What makes them better? The extra layer of fluting spreads out the shock over two layers instead of one, so items inside stay protected from getting crushed. Think about something fragile like a set of precision drill bits or those expensive torque wrenches mechanics rely on daily. For lighter stuff though, single wall boxes work fine if what's inside weighs less than 25 pounds. But when put through rigorous multi surface testing following ISTA 3A standards, these lighter boxes tend to develop dents at around 40% higher rate than double walls do. Still worth considering for small packages where weight isn't an issue.

When to Use Double-Wall for Heavy or Long-Distance Electric Tool Shipments

For heavier tools (anything above 50 pounds) or items heading overseas, double wall construction just makes sense. According to various industry reports, these reinforced boxes cut down on shipping damage claims by around one third when compared to standard single wall options used in online shipping. The extra layer really matters for things like cordless power tool sets containing lithium ion batteries. When those kits get tossed around during rail transport or loaded into cargo holds, the vibrations can actually cause connections between battery terminals to come loose if not properly protected. That's why many manufacturers now specify double wall packaging for their premium products going through international channels.

Cost-Benefit of Added Thickness in Premium Protective Packaging

Although double-wall boxes cost 25—35% more than single-wall versions, their durability often eliminates the need for secondary packaging like foam inserts. Transport modeling shows the higher material cost is offset by reduced returns—delivering a 1.8:1 ROI for retailers shipping premium tools over 300-mile distances.

Adapt Customized Gift Box Design to Shipping Conditions and Environmental Stressors

Matching Box Materials to Global Shipping Conditions

The weather outside affects what goes inside our gift boxes too. For shipments heading to tropical areas, we need special materials that stand up to humidity. Boxes sent through places like Southeast Asia must have adhesives that resist moisture at around 65% relative humidity plus coatings that fight off fungus growth. We've seen real world results from logistics companies who switched to triple layer corrugated board instead of regular single wall designs. Their reports show about 30% better structural strength in those damp environments according to Packaging Digest last year. Makes sense really since nobody wants their presents arriving soggy or damaged after traveling across continents.

Impact of Humidity, Stacking Pressure, and Vibration on Box Integrity

Shipping environments degrade packaging through three main stressors:

- Humidity reduces corrugated strength by up to 50% after 72 hours (ISTA 2022 standards)

- Stacking pressures over 200 PSI in container ships crush 23% of under-engineered boxes (FreightWaves 2024 analysis)

- Sustained vibration causes 18% more edge abrasion in rigid boxes than in flexible designs

Case Study: Optimizing Packaging for Cordless Drill Kits in International Logistics

A power tool manufacturer reduced damage claims by 45% by implementing:

- Climate-adaptive board grades (ECT 55 for ocean freight)

- Die-cut internal trays with non-slip PE coatings

- Perimeter reinforcement strips rated for 6G vibration forces

The redesigned packaging maintained a damage rate below 0.8% across 12,000 shipments over 6-week multimodal cycles.

Emerging Trend: Climate-Responsive Coatings for Durable Customized Gift Boxes

Smart materials now adapt autonomously to environmental changes—hydrogel layers stiffen in high humidity (boosting compression resistance by 40%), while phase-change coatings reflect UV radiation. Early adopters report 60% fewer climate-related packaging failures compared to traditional options (ASTM D4169-23 testing).

Incorporate Structural Design Innovations to Enhance Load-Bearing Performance

Reinforced Corners and Internal Die-Cut Trays for Superior Protection

Load-bearing customized gift boxes must reinforce structural weak points. Multi-layered fiberboard or molded corner inserts mitigate stacking forces, while die-cut internal trays prevent component shifting. A 2025 materials science study demonstrated that dual-material corrugated composites improve load distribution by 22% over single-material designs.

How Closure Systems Contribute to Box Durability Under Load

Interlocking flaps and reinforced adhesive tapes maintain box integrity under dynamic loads. Pressure tests show boxes with overlapping double-lock bases withstand 37% more vertical compression than standard designs—critical for tools over 15 lbs.

Proven Results: 40% Reduction in Damage Claims With Structural Upgrades

Manufacturers using radial corner braces and cross-channel ventilation (to minimize moisture warping) report fewer transit failures. One power tool producer achieved a 40% reduction in damage claims after adopting triple-wall side panels and tool-specific foam inserts, as verified by their 2023 internal logistics audit.

FAQ

What factors determine a box's load-bearing capacity?

A box's load-bearing capacity is determined by material rigidity, wall thickness, and internal support systems.

Why are double-wall corrugated boxes preferred for heavy shipments?

Double-wall corrugated boxes are preferred because they can handle more impact force and provide better protection for heavy items during transit.

How does humidity affect packaging strength?

Humidity can reduce corrugated strength by up to 50% after 72 hours, affecting the integrity of the packaging.

What innovations enhance the durability of customized gift boxes?

Structural design innovations such as reinforced corners, internal die-cut trays, and climate-responsive coatings improve durability.

Table of Contents

- Determine Load-Bearing Requirements Based on Electric Tool Specifications

- Evaluate Material Composition for Maximum Durability in Customized Gift Boxes

- Single-Wall vs. Double-Wall Corrugated: Choosing the Right Protection Level

- Adapt Customized Gift Box Design to Shipping Conditions and Environmental Stressors

- Incorporate Structural Design Innovations to Enhance Load-Bearing Performance

- FAQ